| Regel 30: | Regel 30: | ||

That was the last mechanical hurdle so rebuiling has started now. Only one belt needs to be recreated, but that can only be done after the motor is back on the chassis. When the machine is back in one piece, we will focus on the electronics, starting with the power supply. Fortunately people at the danish datamuseum are also working on their 101 and have a rather good repairlog: http://datamuseum.dk/wiki/Olivetti/Programma_101/Revive | That was the last mechanical hurdle so rebuiling has started now. Only one belt needs to be recreated, but that can only be done after the motor is back on the chassis. When the machine is back in one piece, we will focus on the electronics, starting with the power supply. Fortunately people at the danish datamuseum are also working on their 101 and have a rather good repairlog: http://datamuseum.dk/wiki/Olivetti/Programma_101/Revive | ||

| + | |||

| + | == Electronics == | ||

| + | |||

| + | To test the powersupply, we need a dummyload of about 10ohm at 24v. To get a voltage reading of around 20v on the powerline. Pins are p1f and p1m. | ||

== Links == | == Links == | ||

Versie van 21 aug 2014 09:41

| Project: Repair Olivetti Programma 101 | |

|---|---|

| Naam | Repair Olivetti Programma 101 |

| Door | MacSimski |

| Status | Uitvoer |

| Madskillz | mechanics, electronics, temper control |

| Doel / Omschrijving | |

| Attempt to restore a Programma 101 to working order | |

| Alle Projecten - Project Toevoegen | |

Our Olivetti Programma 101 has been sitting idle in a cellar for at least 10 years. Because of the way the machine is built and its age, all the mechanical parts have gummed up. Grease and oil have turned into a tough goo and the various belts have deteriorated. Checking and fixing the machine is only possible after a thorough cleaning, application of fresh lubricating agents and replacement of all the belts. Afterwards, we will be able to proceed with checking the electronics of this calculator.

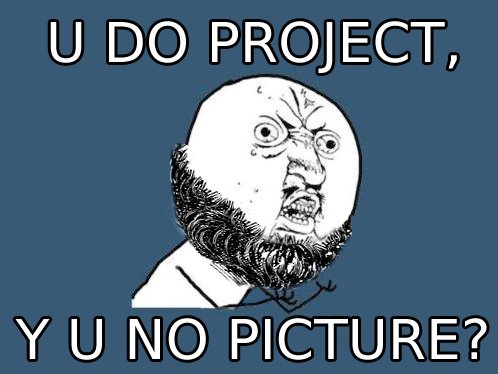

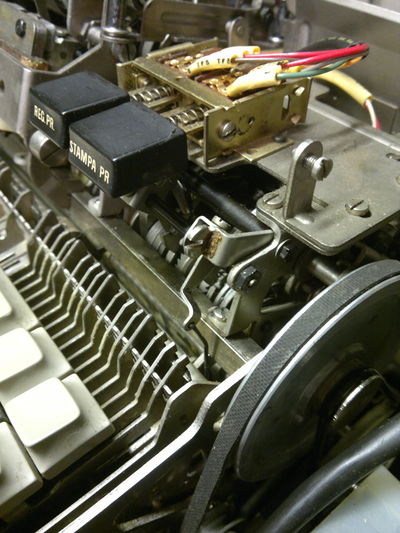

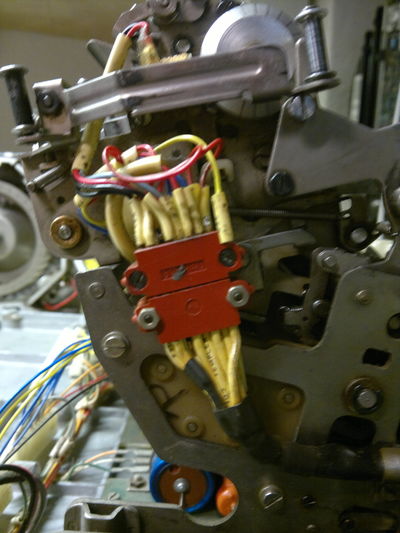

Mechanics

The mechanics are divided into some assemblies, fixed to each other and the chassis with sometimes hard to reach screws. It is the earliest known instance of a RISC processor ("Ridiculus Italian Screw Construction"). Some screws are almost unreachable. So for some screws you need to stick a very long screwdriver completely through the assembly to reach it.

The major units are:

- Keyboard assembly.

- Printer assembly.

- Servo assembly

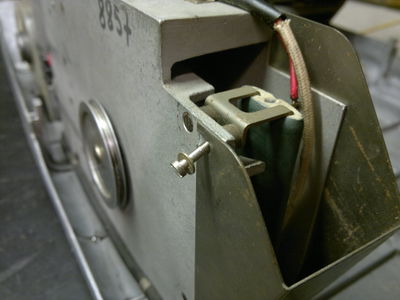

- Card reader assembly.

- Motor.

- Main cooling fan.

Progress

After a first internal inspection it was clear that all the mechanical parts had gummed up by old grease and oil and that all the belts save one had turned into goo. Fortunately the machine was not tampered with or "repaired" by an amateur. We proceeded by taking the machine apart when we encountered the now famous "Reversed Italian Screw Position". Especially the card reader and the electronics cage are fitted in this fashion. I made a long flat srewdriver from a piece of long iron to reach for the deep placed screws. Finding the screw underneath the powersocket took some time as well.

The machine taken apart I focused on getting the mechanics working again. The separate assemblies were taken and submerged in Nebol grease cleaner. Belts were removed with care not to spoil the clean surroundings and the path cleaned with dasty grease remover. Getting the motor running smoothly again turned out to be a strange thing. To get to the gummed up brass bearings, we took apart the motor and cleaned the shaft and bearing with brake-cleaner. After reassembly everything was smooth, but returning the next day we found a gummed up motor on the bench. After a few attempts we discovered that the brass is porous and a piece of oil drenched felt is behind the bearing, regreasing the shaft overnight. So a thorough submerge in nebol fixed that for good.

The pinchroller for the magcards was a different problem. It had gummed up so badly and deformed beyond measurement. 11mm,12mm? we don't know. for now Ive cleaned the rod of its remains and took a measurment on the other intact roller. as it is connected to the pinchroller with a belt and pulleys of the same diameter, I think it could well be the right size: 12mm. The pichroller was restored with car gas tubing with 6mm internal and 12mm outer diameter. the pinchroller rod is 5mm diameter, so shrinktubing is used to fill the gap. works perfectly.

That was the last mechanical hurdle so rebuiling has started now. Only one belt needs to be recreated, but that can only be done after the motor is back on the chassis. When the machine is back in one piece, we will focus on the electronics, starting with the power supply. Fortunately people at the danish datamuseum are also working on their 101 and have a rather good repairlog: http://datamuseum.dk/wiki/Olivetti/Programma_101/Revive

Electronics

To test the powersupply, we need a dummyload of about 10ohm at 24v. To get a voltage reading of around 20v on the powerline. Pins are p1f and p1m.

Links

The Datamuseum in Denmark is restoring their 101.