Uit Hack42

(Nieuwe pagina aangemaakt met '{{Project}}') |

|||

| Regel 1: | Regel 1: | ||

| − | {{Project}} | + | {{Project |

| + | |Naam=BugBlue | ||

| + | |Eigenaar=BugBlue | ||

| + | |Status=Uitvoer | ||

| + | |Skills=Solderen, firmware fixen, schroeven, boren, meten | ||

| + | |Samenvatting=Makerbot een revisie geven zodat die normaal werkt | ||

| + | }} | ||

| + | === Introduction == | ||

| + | Got a makerbot from [http://revspace.nl/ revspace]. Where one of it's members had it sitting on a desk for about a year without any good quality prints I decided to rob them and fix it completely with an overhaul | ||

| + | |||

| + | == The fixes == | ||

| + | # J-Head 0.35 printhead | ||

| + | : The new J-Head extruded behaves much more nicely, doesn't jam up and gives a very nice output | ||

| + | # Teacup firmware | ||

| + | : New teacup firmware makes it possible to use pronterface and slic3r as software. Giving much nicer control, monitoring and easier settings than any of the other old software. | ||

| + | # Rewire | ||

| + | : Since it is a makerbot cupcake CNC with a seperate extruderboard and a steppermotordriver connected to the extruderboard rewirering was needed since the extruder steppermotor is now connected directly to the mainboard. The extruderboard is now the only switching and controlling the temperature of the heated bed and the extruded | ||

| + | : TODO: this might change and we might move all lines to the mainboard. | ||

| + | : New cables and connectors for the hotend are needed | ||

| + | # Printbed | ||

| + | : The original printbed of the makerbot is very unstable this has to change | ||

| + | : TODO: New printbed with glassplate and isolation | ||

| + | # Z threaded rods | ||

| + | : they are bend in very ugly shapes. These need to be replaced | ||

| + | # Calibration | ||

| + | : X Y and Z calibration are very easy. Extruded calibration should be done at the right temperature. | ||

| + | : TODO: extruder recalibration | ||

| + | # Retraction | ||

| + | : Since it takes a *lot* of steps (gearbox) to retract retraction time is slow, retraction is set to only 0.2mm during print | ||

| + | : TODO: lower this value | ||

| + | # Endstops | ||

| + | : There are no endstops | ||

| + | : TODO: install 6 endstops, drill holes to install them and wire them. (easy). | ||

| + | # Grease | ||

| + | : TODO: Apply more. | ||

| + | |||

| + | === Conclusion === | ||

| + | It was a nice desing at some time, however newer firmware and a lot of improvements can make it a very nice and fast printer. | ||

Versie van 13 jul 2012 11:40

| Project: BugBlue | |

|---|---|

| Naam | BugBlue |

| Door | BugBlue |

| Status | Uitvoer |

| Madskillz | Solderen, firmware fixen, schroeven, boren, meten |

| Doel / Omschrijving | |

| Makerbot een revisie geven zodat die normaal werkt | |

| Alle Projecten - Project Toevoegen | |

= Introduction

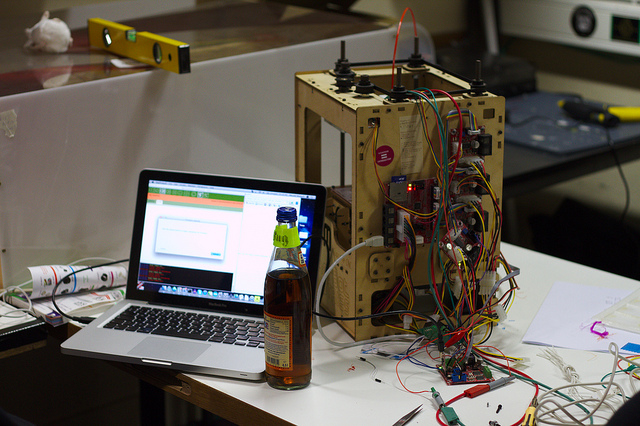

Got a makerbot from revspace. Where one of it's members had it sitting on a desk for about a year without any good quality prints I decided to rob them and fix it completely with an overhaul

The fixes

- J-Head 0.35 printhead

- The new J-Head extruded behaves much more nicely, doesn't jam up and gives a very nice output

- Teacup firmware

- New teacup firmware makes it possible to use pronterface and slic3r as software. Giving much nicer control, monitoring and easier settings than any of the other old software.

- Rewire

- Since it is a makerbot cupcake CNC with a seperate extruderboard and a steppermotordriver connected to the extruderboard rewirering was needed since the extruder steppermotor is now connected directly to the mainboard. The extruderboard is now the only switching and controlling the temperature of the heated bed and the extruded

- TODO: this might change and we might move all lines to the mainboard.

- New cables and connectors for the hotend are needed

- Printbed

- The original printbed of the makerbot is very unstable this has to change

- TODO: New printbed with glassplate and isolation

- Z threaded rods

- they are bend in very ugly shapes. These need to be replaced

- Calibration

- X Y and Z calibration are very easy. Extruded calibration should be done at the right temperature.

- TODO: extruder recalibration

- Retraction

- Since it takes a *lot* of steps (gearbox) to retract retraction time is slow, retraction is set to only 0.2mm during print

- TODO: lower this value

- Endstops

- There are no endstops

- TODO: install 6 endstops, drill holes to install them and wire them. (easy).

- Grease

- TODO: Apply more.

Conclusion

It was a nice desing at some time, however newer firmware and a lot of improvements can make it a very nice and fast printer.